Synthetic Viewing Helps to Reduce Maintenance Costs

Recently, Heemskerk Innovative Technology has successfully presented the results of the Synthetic Viewing study to a representative of ITER IO.

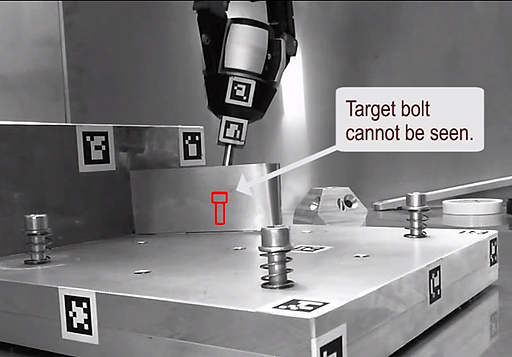

Synthetic Viewing facilitates maintenance in inaccessible environments, by enriching camera images with augmented features (Augmented Reality), or by allowing the operator to work in a calibrated virtual environment (Virtual Reality), without direct camera images.

Maintenance in inaccessible environments (e.g. deep sea, space, nuclear) is often hindered by the limited view of the action. In ITER , an experimental fusion reactor being built in Cadarache, southern France, the circumstances are so dangerous that maintenance activities on the reactor have to be performed remotely. This is called Remote Handling. Commissioned by ITER Organization, Heemskerk Innovative Technology BV presented a prototype Synthetic Viewing system, in cooperation with TNO and FOM Institute DIFFER and based on previous R & D work carried out by TNO together with the flag of ITER-NL.

The system analyzes Synthetic Viewing camera images to identify and track relevant objects in the scene. The object location and orientation is calibrated against the spatial information from a CAD model and updated in real-time. The calibrated models form the basis for adding augmented features, which can be projected as an overlay on the camera images, or displayed as completely artificial and virtual reality scenes with high contrast and resolution from a user-selectable angle. This Synthetic Viewing the system makes it possible for example occluded (hidden) to make visible features or to create a better approach to perform the task. An experiment with experienced maintenance personnel showed that that the system gives users a clear and intuitive understanding of the environment, and demonstrated that certain actions can be performed significantly faster and safer.

Heemskerk Innovative Technology BV (HIT) routinely performs remote handling compatibility analyses in close cooperation with the FOM Institute DIFFER in the Remote Handling Study Centre. The purpose of these analyses is to increase the efficiency of maintenance work so that the reliability and availability of the machinery to be optimized, the cost and turnaround time of the maintenance is reduced. By better view of the maintenance operations are also made fewer mistakes. Director Cock Heemskerk: “The Synthetic Viewing System is a powerful extension of HIT’s portfolio of analysis tools for maintenance and operational support in remote handling”.